We urgently need the metal parts that are used in respirators motor. Your help will be highly appreciated and most likely will save lives.

Overview:

The Challenges of Covid-19

Ventilators, often referred to as life support machines are used in intensive care units for patients who cannot breathe on their own. In the earliest days of the COVID-19 pandemic, U.S.A and European government officials asked ventilator manufacturers to design an affordable and scalable hospital-grade ventilator to address anticipated nationwide shortages. To avoid undermining the already-strained supply chain, the design needed to be created with other readily available machine parts not earmarked for specialized medical use.

Design of Ventilators

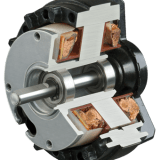

Ventilators require precise, reliable pump solutions to accurately control volume, pressure and flow. Brushless DC motors and high-performance motor drives are the perfect choices for ventilators, providing small size, high torque density, precise motor speed control and low noise; the ideal solution for regulated airflow.

Problem:

An Urgent Need for Ventilators

In mid of March 2020, when medical experts were projecting massive shortages of ventilators needed for COVID-19 patients, government officials approached the ventilator manufacturer for help. There are a lot of people infected with the coronavirus, it urgently needs the machined parts that are used in ventilator motors. Local component factories could not fulfill huge demand in a short period. In addition, Ventilator engineers and partial production operators were forced to work from home by the pandemic’s shelter-in-place mandates. In the mid of March, our customer contacted Boly for urgent help.

Approach:

On the highest priority

In fact, we did not have much knowledge about COVID-19 at the beginning; ventilators become the only medical device that can save more lives. Therefore our management makes a critical decision by re-schedule our production line and pivoting our entire team to build ventilator components. We targeted to make the first 50000 sets of components and delivered them to USA and European customers in 2 weeks.

Creating a More Resilient Supply Chain

One of the most important objectives of the Emergency Ventilator project was to not undermine existing medical supply chains, already under heavy strain from different states competing for the same resources. Boly assisted customers to build other readily available components not earmarked for specialized medical use by CNC machining and assembly service.

Result:

Critical For Success

Fortunately, hospitals have so far avoided the ventilator shortages projected in a worst-case scenario. However, as experts warn of a “second wave” or “mutations” of the coronavirus during flu season, Boly would be one of the manufacturing partners around the world. We are ready to scale up production in case a sudden need for ventilator components arises.

More about our medical machined parts solution – Learn more

- Year:

- 2020

- Category:

- Medical

- Client:

- Ventilator supplier